Physical Address

304 North Cardinal St.

Dorchester Center, MA 02124

Physical Address

304 North Cardinal St.

Dorchester Center, MA 02124

A small flaw bump on the upper heat press platen might seem insignificant, but it can cause major headaches for heat transfer professionals. This article will explore the causes, effects, and solutions for these pesky imperfections that can wreak havoc on your heat press projects. We’ll cover everything from identifying the problem to maintaining your equipment for optimal performance.

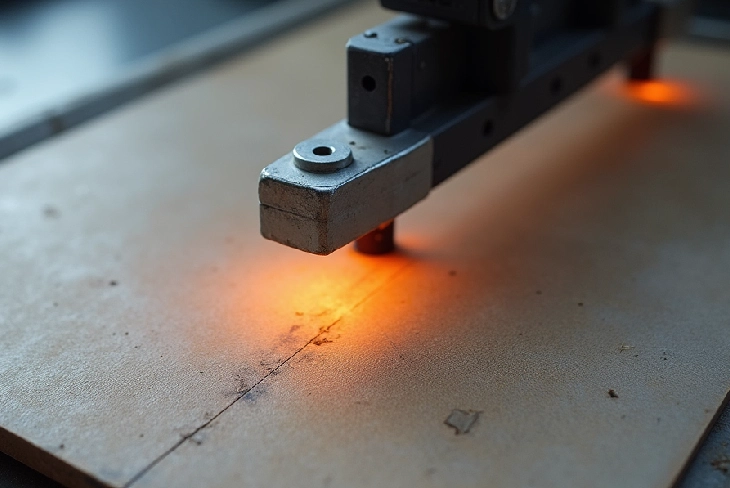

Small Flaw Bump on Upper Heat Press Platen are minor imperfections or raised areas on the surface of the heating element. These bumps can be as small as a grain of sand or as large as a pea, but even the tiniest flaw can cause significant issues in heat transfer quality.

Flaw bumps often occur due to wear and tear, improper use, or manufacturing defects. They can develop over time as the platen is subjected to repeated heating and cooling cycles, or they may result from accidental impacts during operation or maintenance.

The presence of these bumps can lead to uneven pressure distribution across the platen surface. This unevenness can result in inconsistent heat transfer, potentially ruining your projects and wasting materials.

Spotting a small flaw bump on your upper heat press platen isn’t always easy, but it’s crucial for maintaining the quality of your work. Start by performing a visual inspection of the platen surface when it’s cool. Run your fingers gently over the surface to feel for any irregularities.

When the platen is heated, flaw bumps can become more noticeable. Look for areas where the heat-sensitive paper or transfer material doesn’t make full contact with the platen. These spots might appear as lighter areas or sections where the transfer doesn’t adhere properly.

Signs of uneven pressure distribution include inconsistent color saturation in your transfers, areas where the design doesn’t fully adhere, or sections where the material appears scorched or overheated. If you notice any of these issues, it’s time to investigate your platen for potential flaw bumps.

Flaw bumps don’t just appear out of nowhere. They’re often the result of several factors that affect your heat press over time. Understanding these causes can help you prevent them from occurring in the first place.

Wear and tear is a common culprit. Over time, the repeated heating and cooling of the platen can cause small imperfections to develop. This is especially true if you’re using your heat press frequently or for long periods.

Improper cleaning methods can also lead to flaw bumps. Using abrasive materials or harsh chemicals can damage the platen surface, creating small scratches or pits that eventually become more noticeable bumps.

Uneven pressure settings are another potential cause. If you consistently apply too much pressure in certain areas, it can lead to deformation of the platen surface over time. Similarly, overheating issues can cause the platen material to warp or develop bumps.

Prevention is always better than cure, and this holds true for flaw bumps on your heat press platen. By implementing some simple preventive measures, you can extend the life of your equipment and maintain the quality of your heat transfers.

Proper cleaning techniques are crucial. Always clean your platen when it’s cool, using a soft cloth and a mild cleaning solution designed for heat press equipment. Avoid abrasive materials or harsh chemicals that could damage the surface.

Establish a regular maintenance schedule for your heat press. This should include not only cleaning but also checking for any signs of wear or damage. Catching potential issues early can prevent them from developing into more serious problems.

Using protective covers when the heat press isn’t in use can help shield the platen from accidental impacts or environmental factors that could cause damage. These covers can be especially useful if you work in a busy or dusty environment.

If you’ve discovered a small flaw bump on your upper heat press platen, don’t panic. There are several approaches you can take to address the problem, depending on its severity.

For minor bumps, you might be able to resolve the issue yourself. Try using a fine-grit sandpaper to gently smooth out the bump. Be extremely careful not to damage the surrounding area, and always test the platen after any DIY fixes to ensure you haven’t made the problem worse.

When the flaw bump is more significant or you’re not comfortable attempting a fix yourself, it’s time to seek professional help. Many heat press manufacturers offer repair services or can recommend authorized technicians who can address the issue.

In some cases, especially with older equipment or severe damage, replacement might be the best option. While this can be a significant expense, it’s often more cost-effective in the long run than continuing to struggle with a flawed platen.

Regular maintenance is key to preventing flaw bumps and ensuring the longevity of your heat press. Implementing a few simple routines can make a big difference in the performance and lifespan of your equipment.

Develop a daily cleaning routine for your heat press. This doesn’t need to be time-consuming – a quick wipe-down with a soft, damp cloth when the platen is cool can help prevent buildup of residues that could lead to damage over time.

Conduct periodic inspections of your heat press, paying close attention to the platen surface. Look for any signs of wear, damage, or developing imperfections. Catching these issues early can prevent them from becoming more serious problems.

Don’t forget about the moving parts of your heat press. Regularly lubricating hinges, levers, and other moving components can help prevent stress on the platen and reduce the likelihood of accidental impacts that could cause flaw bumps.

A small flaw bump on the upper heat press platen can have a surprisingly large impact on the quality of your work. Understanding these effects can help you recognize when you might be dealing with a platen issue.

Inconsistent heat transfer is one of the most common problems caused by flaw bumps. Areas of your design may not receive enough heat, resulting in poor adhesion or faded colors. On the flip side, the raised areas of the bump might receive too much heat, potentially scorching or damaging your materials.

Uneven pressure distribution is another significant issue. The bump creates high-pressure points on your transfer, which can lead to uneven wear on your materials or inconsistent results across different projects.

Over time, a flaw bump can potentially cause damage to your materials. Fabrics might become stretched or distorted in the area of the bump, and transfer papers could wrinkle or tear. This not only affects the quality of your current project but can also lead to wasted materials and increased costs.

If you’re in the market for a new heat press, or if you’re considering replacing a platen with flaw bumps, it’s important to choose equipment that will serve you well in the long run.

Look for heat presses with high-quality platens made from durable materials. Some manufacturers use specially treated metals or coatings designed to resist wear and prevent the formation of flaw bumps.

Consider the warranty and support offered by the manufacturer. A good warranty can provide peace of mind and protect your investment. Additionally, responsive customer support can be invaluable if you do encounter issues with your equipment.

Don’t forget to read reviews and ask for recommendations from other professionals in your field. Their real-world experiences can provide valuable insights into the durability and performance of different heat press models.

Small flaw bumps on the upper heat press platen might seem like a minor issue, but they can have a significant impact on the quality of your work and the longevity of your equipment. By understanding what causes these bumps, how to identify them, and how to prevent them, you can maintain the performance of your heat press and ensure consistent, high-quality results.

Remember, regular maintenance and prompt attention to any developing issues are key to preventing flaw bumps from becoming major problems. Whether you’re dealing with a small imperfection or considering a full platen replacement, addressing the issue promptly will save you time, money, and frustration in the long run.

By implementing the tips and techniques discussed in this article, you’ll be well-equipped to keep your heat press in top condition, ensuring smooth operations and professional-quality heat transfers for years to come.